Healthcare professionals and patients depend on magnetic resonance imaging (MRI) and CT scan technology to analyze soft tissues and organs in the body, detecting a range of issues from degenerative diseases to tumors in a non-invasive manner. The MRI machine utilizes a powerful magnetic field and computer-generated radio waves to generate cross-sectional images. Therefore, the quality of the MRI is contingent on the uniformity of the magnetic field – even the slightest trace of magnetism inside an MRI scanner can disrupt the field and diminish the quality of an MRI image.

How an MRI Works at a High Level

The MRI machines we are familiar with today operate on the principle of nuclear magnetic resonance (NMR). Specifically, the molecules within the human body contain hydrogen, and the nucleus of the hydrogen atom consists of a single proton that acts as a magnet with a north and south pole. When a magnetic field is applied, their spins, a property of subatomic particles, align uniformly. As a patient is placed inside the MRI scanner tube, the spins of the protons in the body’s molecules align, all facing the same direction, akin to a marching band practicing on a football field.

Nevertheless, even the most minor variation in the magnetic field can cause protons to align in different ways, which means they will not respond the same way to the stimulus. These discrepancies can confound the detection algorithms. In reality, these irregular detections, excessive signal noise, or random fluctuations in signal intensity can result in grainy images. A low-quality image could potentially lead to an incorrect diagnosis and, as a result, misguided treatment decisions.

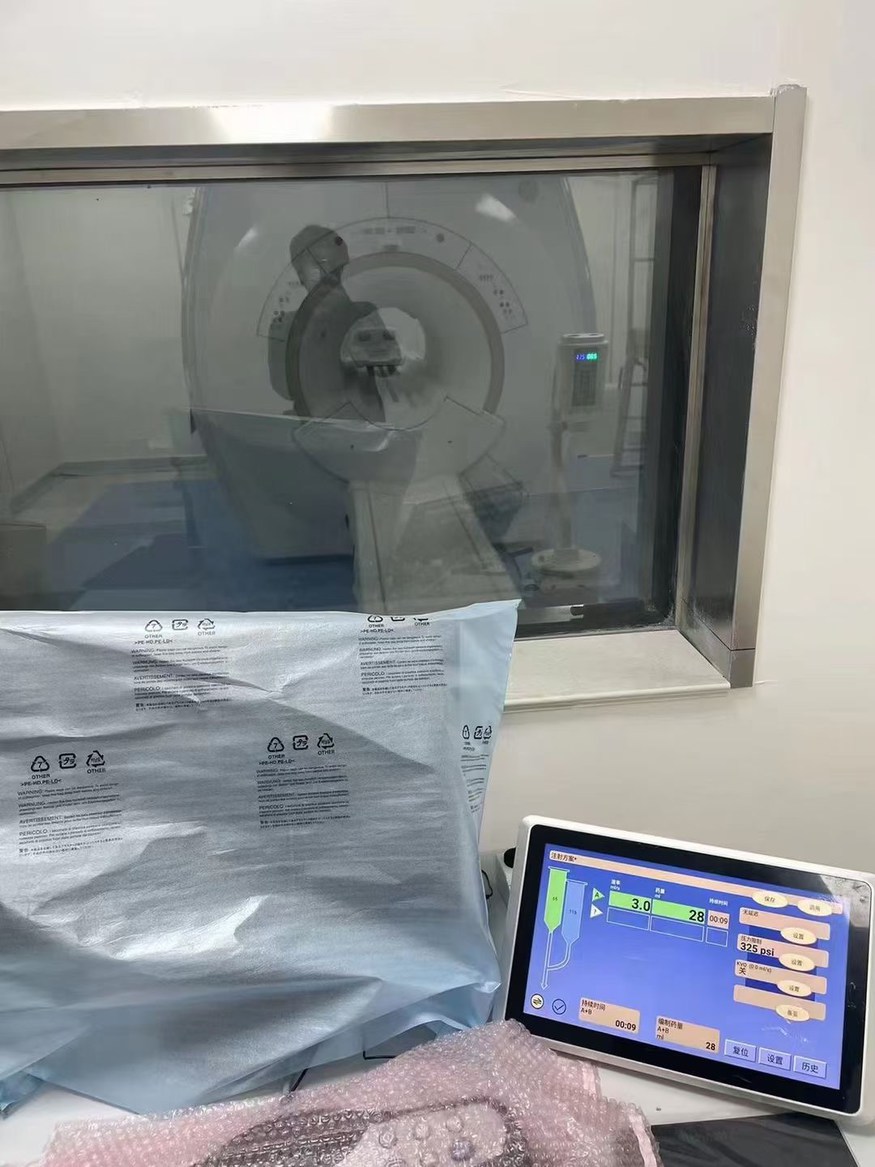

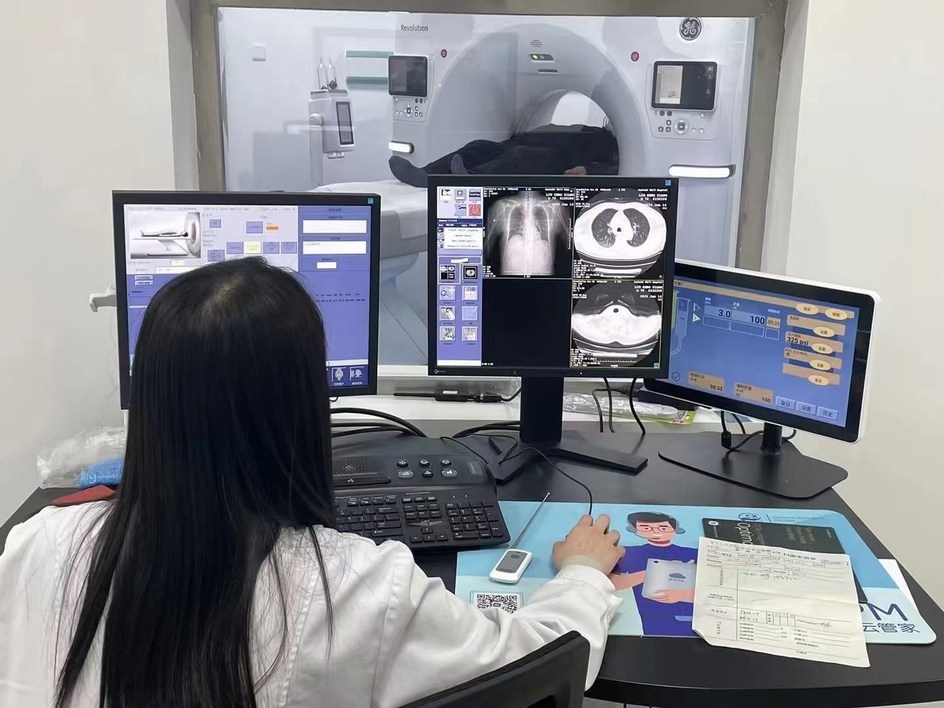

(As we all know, imaging needs to be completed through the medium -contrast agent, and it needs to be input into the patient’s body through high pressure injectors as well as the syringe and tubes. LnkMed is a manufacturer that specializes in assisting in the delivery of contrast agents. Its independently developed MRI contrast injector, CT scan injector and DSA injector have been distributed in hospitals in many countries to provide services for medical care. Our injectors are waterproof, highly flexible, and convenient for medical staff to move and operate; they use Bluetooth communication, the operator don’t need to spend much time on positioning and setting up; free replacement parts if after-sales service is available. LnkMed has been committed to providing high-quality products and services for radiology and imaging.

If you are interested, you are welcome to inquire via this email: info@lnk-med.com)

Component Material Choice is Crucial

The presence of magnetic components within the MRI scanner tunnel has the potential to disrupt the uniformity of the field, and even the tiniest amount of magnetism could impact the quality of the MRI image. As a result, it is crucial for medical device manufacturers to seek out components, such as fixed capacitors, trimmer capacitors, inductors, and connectors, that are constructed from high-purity metals devoid of any measurable magnetism.

Adhering to this requirement begins with rigorous traceability and testing procedures, as well as a solid foundation in materials science expertise. For instance, numerous capacitors are engineered with a nickel barrier finish to preserve solderability; nevertheless, the magnetic properties of nickel render the capacitor unsuitable for use in imaging applications. Likewise, commercial brass, another frequently utilized material, is also unsuitable for these purposes.

Such meticulous attention to detail at the component level prevents distortion and reduces the necessity for image correction. Consequently, clinicians can effectively examine and diagnose patients without requiring more invasive procedures.

Post time: Mar-13-2024